Corrosion Under Insulation Enabling Risk-Based Inspection

As an industry leader for advanced NDT, NDE Solutions undertakes corrosion under insulation (CUI) for enhanced risk-based inspection (RBI).

We train and mentor our local personnel, whilst building partnerships with leading technology manufacturers such as evoSonic, Eddyfi & Guided Ultrasonics Ltd (GUL)…

Our Difference

Deploying an arsenal of advanced methods, NDE offers a one-stop shop for CUI campaigns using the below techniques.

- Pulsed eddy current (PEC) provides quick, efficient & repeatable inspection, capable of inspecting up to 30m of piping per shift via rope access.

- Open vision is a real time radiography technique which enables access to challenging areas such as pipe supports, with instant assessment.

- Long Range Ultrasonic Testing (LRUT) is capable of inspecting substantial distances from a single point of access. This technology is an efficient method for buried piping and not easily accessible lines.

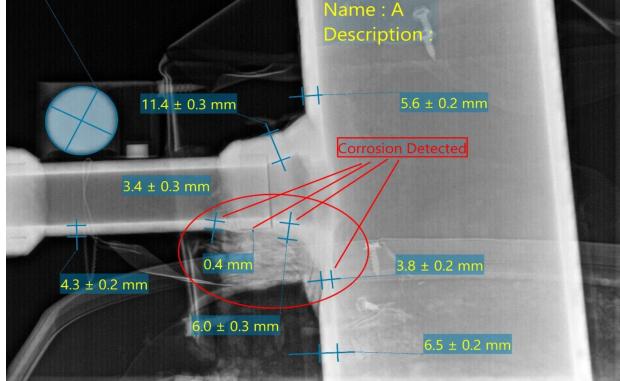

DRT finding and stopping potential LOC event 0.4mm RWT at socklet on live asset.

CUI is a difficult corrosion mechanism to detect with no single non-destructive testing (NDT) method able to provide complete detection capabilities or application. Estimated remediation & inspection campaigns for CUI across complex asset industries are financially costly for operators.

Historical methods of inspection have been to remove large portions of cladding to complete conventional methods. This effectively results in 50% of integrity budgets being spent before any inspection data is captured or remediation has begun.

- Digital radiography (DRT) provides accurate and clear imagery for dead legs and small-bore fittings which are prone To CUI. DRT is a reliable method to assess integrity under insulation.

- Corrosion under pipe supports (CUPS) In partnership with GUL and other like-minded technology providers, NDE is able to deliver unrestricted circumferential & axial integrity information for pipe supports. Not one inspection method can meet all the challenges of CUI. However, our integrated and broad ranging suite of inspection solutions, allows NDE to safeguard your critical assets.

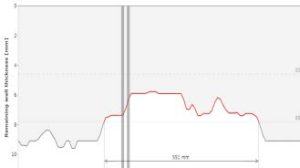

Workflow of Corrosion Under Pipe Support

Acquisition of data via automated scanning enables live analysis.

Verification via ultrasonics & visual inspection after contact point removal.

Data provided allows reporting of susceptible areas or corrosion and/or erosion.

Planning

Ensuring productivity during the entire campaign through knowledge sharing of access & staggered phases.

Execution

Professionally executing advanced inspection in major hazard facilities via rope access or elevated work platform.

Reporting

NDE is perceptive to your needs and ensures that CUI campaign reports can be utilized for RBI planning.

Outcome

Our dedicated and advanced team brings passion for advanced technology and innovative solutions to enable effective inspection for CUI.