Robotic Tank Corrosion Assessments

Tank failure event aftermath

Over four years, NDE Solutions delivered $6.5 million in direct cost savings for BHP, OD’s tank corrosion assessment program by reducing inspection expenses while improving asset management efficiency. Our proprietary, in-house developed technology—born from extensive R&D—provides faster, more reliable, and higher-quality data than any competitor. This enables smarter decision-making, optimized maintenance strategies, and significantly reduced operational risk, ensuring both cost efficiencies and long-term asset integrity.

The Challenge

A tank failure within a similar Australian site highlighted the importance and urgent need of early detection of integrity concerns within critical tank assets. NDE Solutions was engaged by BHP Olympic Dam to assess the integrity of above-ground storage tanks. These tanks, some of which contain acids for chemical processing are hugely integral to the effective operations of the mine site. As such, any failure could result in millions in lost revenue whilst placing personnel and plant at risk. NDE was engaged to consistently deliver rapid, detailed inspections to detect risks early, minimising operational disruptions while enhancing safety of plant and personnel onsite.

Our technology driven solution

Our Phased Array Ultrasonic (PAUT) remotely operated scanners provide full coverage, high-resolution imaging of the tank integrity. Our team’s understanding of the technical solution as well as our ability to innovate with existing technologies, such as the RMS, allowed us to improve scanner efficiency. This resulted in data acquisition which is far more efficient and precise than alternate methods.

High fidelity, allowing accurate and rapid findings

The inspection followed a streamlined process of firstly deploying the RMS crawler, capturing 100% high-resolution PAUT data, and conducting real-time or end-of-day analysis based on client preferences. Close coordination with BHP minimised disruptions, ensuring smooth integration with simultaneous operations.

Demonstrating successful results to our clients

NDE Solutions has uncovered previously unidentified integrity concerns, enabling BHP to make informed decisions regarding risk isolation and repair scheduling. Key benefits of inspecting high value assets in-service included reduced downtime, improved safety, and significant cost savings through preemptive and proactive maintenance planning.

Client feedback and lessons learned

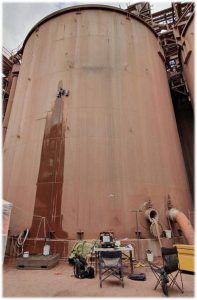

RMS unit in operation without

need of scaffold

BHP has expanded NDE Solutions’ role following a successful initial trial in 2020. Since then, hundreds of tanks have been inspected, with the ongoing partnership driving continuous improvements and reinforcing NDE Solutions’ reputation for proactive, reliable service.

The NDE Solutions difference

This project underscores NDE Solutions’ core values of professionalism and productivity. As the partnership with BHP grows, NDE Solutions remains dedicated to advancing inspection technologies and ensuring the safety and longevity of Australia’s critical infrastructure. NDE Solutions is a sovereign, Australian owned test and inspection company that has demonstrated a willingness to invest in advanced inspection technologies and develop high-end solutions. We are a trusted partner to our clients for critical NDT and inspection services and are proud to be an award-winning firm, having being named Santos’ Contractor of the Year in 2024.

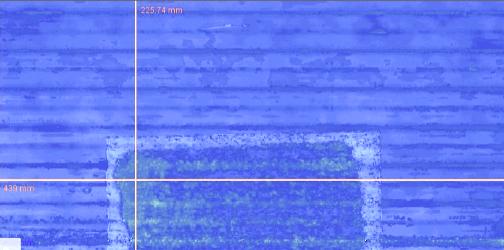

Scan example 1: Ability to resolve corrosion under patch repair plate from external surface

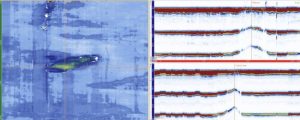

Scan example 2: Identification of internal corrosion feature, raised for repair during next planned shutdown